The Technology Behind Instant Railway Braking

Introduction

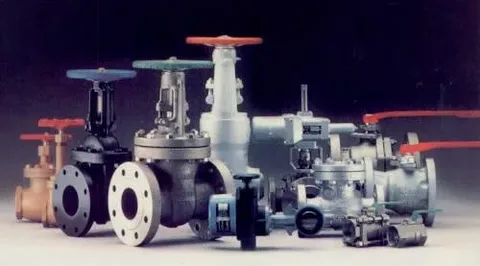

The railway emergency valve market focuses on critical safety components used in railway braking systems to immediately apply brakes during emergency situations. Emergency valves are designed to rapidly release air pressure from the brake pipe, triggering an instant braking response across the entire train. These valves are essential for preventing accidents caused by overspeeding, signal violations, mechanical failures, or unexpected obstacles on tracks. Used in locomotives, passenger coaches, metro systems, and freight wagons, railway emergency valves form a core part of fail-safe railway operations. As rail networks expand and train speeds and loads increase, the reliability and responsiveness of emergency valve systems have become more important than ever.

Market Drivers

The market is driven primarily by rising emphasis on railway safety and regulatory compliance. Railway authorities across the world mandate strict braking and emergency response standards, making emergency valves a compulsory component in rolling stock. Growth in passenger rail, metro, and high-speed rail networks increases demand for advanced braking safety systems. Expansion of freight rail operations, especially heavy-haul and long-distance trains, further supports market growth as emergency braking reliability is critical under high loads. Modernization and refurbishment of aging rail fleets also contribute, as older mechanical valves are replaced with more responsive and durable designs. Increasing focus on accident prevention and operational risk reduction continues to strengthen demand.

Market Challenges

Despite steady demand, the railway emergency valve market faces challenges related to durability, maintenance, and system integration. Emergency valves operate under high pressure, vibration, and varying temperature conditions, which can lead to wear and performance degradation over time. Ensuring consistent response speed and leak-free operation throughout long service intervals is a major technical challenge. Compatibility with different braking systems and rail standards across regions adds complexity to design and certification. Maintenance access can be difficult in tightly packed brake assemblies, increasing service time and costs. Additionally, cost pressure from rail operators may limit rapid adoption of advanced valve technologies in price-sensitive markets.

Market Opportunities

The market offers strong opportunities through technological advancements and safety-focused innovation. Development of corrosion-resistant materials and improved sealing technologies enhances valve durability and reliability. Integration of sensors for pressure monitoring and fault detection enables predictive maintenance and faster response to system issues. Growth of electronically controlled pneumatic braking systems creates demand for emergency valves that integrate seamlessly with digital control architectures. Emerging rail markets investing in new passenger and freight infrastructure present opportunities for large-scale deployment of modern emergency valve systems. Retrofit programs for existing fleets also offer steady aftermarket potential.

Regional Insights

Regional demand varies based on rail infrastructure scale, safety regulations, and fleet modernization activity. Asia-Pacific dominates the market due to extensive rail networks and high train frequency in countries such as China and India. Ongoing metro expansion and freight corridor development support strong demand for emergency braking components. Europe shows steady growth driven by strict safety regulations and continuous upgrading of passenger and freight rolling stock. North America maintains stable demand supported by large freight rail operations and safety compliance requirements. The Middle East is an emerging market with growing rail projects, while Latin America and Africa show gradual growth linked to railway infrastructure development and safety improvements.

Future Outlook

The future of the railway emergency valve market will be shaped by digital integration, reliability enhancement, and standardization. Emergency valves will increasingly be designed to work alongside electronic braking and train control systems, ensuring faster and more coordinated emergency responses. Use of lightweight and high-strength materials will improve performance while reducing maintenance needs. Standardized designs across fleets may simplify maintenance and spare part management. As train speeds, automation levels, and safety expectations rise, demand for highly responsive and fail-safe emergency valve systems will continue to grow steadily.

Conclusion

The railway emergency valve market is a vital segment of the global railway safety ecosystem. By enabling rapid and reliable emergency braking, these valves protect passengers, cargo, rolling stock, and infrastructure. While challenges related to durability, maintenance, and cost remain, increasing rail activity and stricter safety standards continue to drive market demand. Continuous innovation and fleet modernization will ensure that railway emergency valves remain essential components supporting safe and efficient rail operations worldwide.

- Art

- Education et Formation

- Crafts

- Sciences et Technologies

- Economie

- Politique

- Actualité

- Littérature

- Divertissement

- Histoire

- Health

- Actualité

- Shopping & Commerce

- Music

- Agriculture & élevage

- Voyage et Evènementiel

- Beauté & esthétique

- Religion

- Festival

- Sports

- Fête

- Musique

- Autres