Abrasive Waterjet Cutting Machine Market Trends and Opportunities

Introduction

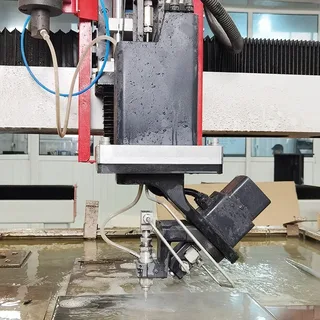

The abrasive waterjet cutting machine market is a key segment of the advanced manufacturing and precision cutting equipment industry, focused on systems that use high-pressure water mixed with abrasive materials to cut a wide range of hard and soft materials. Abrasive waterjet cutting machines are capable of processing metals, ceramics, composites, stone, glass, and alloys with high accuracy and minimal thermal impact. Unlike laser or plasma cutting, waterjet cutting does not generate heat-affected zones, preserving material properties and dimensional integrity.

As manufacturers increasingly work with advanced materials and complex geometries, demand for versatile and precise cutting technologies is rising. Abrasive waterjet cutting machines are widely used across industries such as aerospace, automotive, electronics, metal fabrication, stone processing, and defense. Continuous improvements in pump technology, software control, and automation are driving steady growth in the global abrasive waterjet cutting machine market.

Market Drivers

One of the primary drivers of the abrasive waterjet cutting machine market is the growing demand for precision cutting without thermal distortion. Industries such as aerospace and automotive require tight tolerances and high material integrity. Waterjet cutting ensures accurate cuts without altering mechanical properties, making it ideal for critical components.

Increasing use of advanced and hard-to-machine materials is another major growth driver. Materials such as titanium alloys, hardened steel, composites, and ceramics are difficult to process using conventional cutting methods. Abrasive waterjet machines offer the flexibility to cut these materials efficiently, supporting broader adoption across high-performance manufacturing sectors.

Growth in custom and small-batch manufacturing also supports market expansion. Abrasive waterjet cutting machines are well-suited for low-volume, high-mix production environments where flexibility and quick changeovers are essential. This aligns with the growing trend toward customized and on-demand manufacturing.

Market Challenges

Despite strong demand, the abrasive waterjet cutting machine market faces several challenges. High initial investment cost is a significant barrier, particularly for systems equipped with ultra-high-pressure pumps, advanced motion controls, and automation features. Small and medium-sized enterprises may find it difficult to justify the upfront expenditure.

Operating costs also present challenges. Abrasive materials, water consumption, energy usage, and regular maintenance contribute to higher operating expenses compared to some alternative cutting technologies. Managing consumable costs while maintaining cutting performance is a key concern for end users.

Complex system maintenance and technical skill requirements further affect adoption. Proper operation and upkeep of high-pressure pumps, nozzles, and cutting heads require trained personnel. Lack of skilled operators can limit productivity and increase downtime.

Market Opportunities

Technological advancements present significant opportunities for the abrasive waterjet cutting machine market. Development of more energy-efficient pumps, improved abrasive delivery systems, and intelligent software controls is enhancing cutting speed, accuracy, and cost efficiency. Integration of CNC and CAD/CAM software enables complex contour cutting and automation.

The expansion of aerospace and electric vehicle manufacturing offers another major opportunity. These industries rely heavily on lightweight alloys and composites, which are ideally suited for waterjet cutting. Increasing investment in these sectors is expected to drive sustained demand for advanced waterjet systems.

Emerging markets represent strong long-term growth potential. Rapid industrialization, infrastructure development, and growth in metal fabrication and stone processing industries in developing regions are increasing demand for precision cutting solutions. Local manufacturing and cost-optimized machines will further support market penetration.

Regional Insights

North America holds a significant share of the abrasive waterjet cutting machine market due to strong aerospace, automotive, and defense manufacturing bases. High adoption of advanced manufacturing technologies supports steady demand across the region.

Europe represents another important market, driven by precision engineering, automotive production, and aerospace manufacturing. Emphasis on quality, material efficiency, and sustainability supports widespread use of waterjet cutting systems.

Asia-Pacific is expected to witness the fastest growth during the forecast period. Expanding manufacturing capacity, infrastructure projects, and increasing adoption of advanced cutting technologies in countries such as China, India, and Southeast Asia are driving strong market expansion.

Future Outlook

The future of the abrasive waterjet cutting machine market is closely linked to advancements in automation, digital manufacturing, and material science. Machines are expected to become more efficient, intelligent, and integrated with smart factory systems. Predictive maintenance, remote monitoring, and automated abrasive recycling will further enhance operational efficiency.

As industries continue to demand flexible, precise, and material-friendly cutting solutions, abrasive waterjet technology will remain highly relevant. Long-term market growth will be supported by advanced material adoption, customization trends, and continuous innovation in cutting equipment design.

Conclusion

The abrasive waterjet cutting machine market plays a vital role in modern manufacturing by enabling precise, versatile, and heat-free cutting of a wide range of materials. Driven by demand for advanced material processing, precision manufacturing, and flexible production, the market continues to grow steadily worldwide. While challenges related to cost, consumables, and technical complexity persist, opportunities in automation, aerospace and EV manufacturing, and emerging markets are strengthening long-term prospects. As manufacturing processes evolve toward higher precision and flexibility, abrasive waterjet cutting machines will remain essential tools in advanced production environments.

- Art

- Education et Formation

- Crafts

- Sciences et Technologies

- Economie

- Politique

- Actualité

- Littérature

- Divertissement

- Histoire

- Health

- Actualité

- Shopping & Commerce

- Music

- Agriculture & élevage

- Voyage et Evènementiel

- Beauté & esthétique

- Religion

- Festival

- Sports

- Fête

- Musique

- Autres