Can Investing In Plastics Mould Enhance Operational Sustainability?

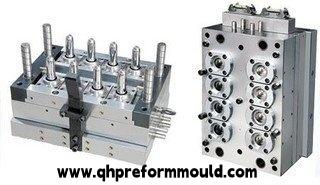

Precision, durability, and efficiency define professional manufacturing, and selecting the right Plastics Mould is essential to achieving these standards. Reliable moulds produce pieces with uniform dimensions, consistent thickness, and superior finish, supporting both operational and aesthetic goals.

Technical performance impacts every stage of production. Accurate alignment prevents material flow issues, reduces defects, and ensures each piece meets design specifications. Smooth internal surfaces allow easy release, improving consistency and overall quality.

Durable construction is crucial. Industrial-grade moulds withstand repeated cycles, resist wear, and maintain exact tolerances. This longevity reduces downtime, minimizes replacement costs, and ensures uninterrupted production. Investing in quality equipment pays dividends in reliability and efficiency.

Operational efficiency benefits from thoughtful design. Fast ejection, easy cleaning, and low-maintenance features keep workflow smooth, reduce handling issues, and protect operator safety. These practical considerations are vital in high-volume manufacturing environments.

Sustainability increasingly influences mould design. Efficient use of material, minimal waste, and optimized energy consumption contribute to environmentally responsible production practices, benefiting both operations and public perception.

Even subtle details, such as polished surfaces and refined cavity geometry, affect the quality and appearance of finished items. These enhancements prevent common defects, improve surface finish, and reinforce a company’s professional standards.

Collaborating with a trusted supplier ensures access to moulds engineered for precision, flexibility, and long-term reliability. Professional support allows manufacturers to select equipment tailored to specific needs, balancing efficiency, quality, and durability.

High-performance Plastics Mould tools are not just equipment; they are foundational components influencing workflow, quality, and product excellence. Selecting the right mould supports consistent output, operational efficiency, and sustainable manufacturing practices.

To explore high-quality, reliable Plastics Mould solutions, visit https://www.qhpreformmould.com/product/plastic-preform-moulds/

- Art

- Education et Formation

- Crafts

- Sciences et Technologies

- Economie

- Politique

- Actualité

- Littérature

- Divertissement

- Histoire

- Health

- Actualité

- Shopping & Commerce

- Music

- Agriculture & élevage

- Voyage et Evènementiel

- Beauté & esthétique

- Religion

- Festival

- Sports

- Fête

- Musique

- Autres