Next-Generation Biomanufacturing Market Insights and Forecast Projections 2032

Introduction

The Next-Generation Biomanufacturing Market represents a significant transformation in the field of biotechnology and life sciences, emphasizing advanced production methods for biologics, vaccines, cell therapies, and other biopharmaceutical products. It focuses on innovative technologies that enhance efficiency, scalability, and sustainability in manufacturing processes. This includes continuous bioprocessing, single-use systems, automation, artificial intelligence (AI)-driven process control, and modular production facilities.

The market is vital to global healthcare and pharmaceutical innovation, supporting the rapid production of complex biological drugs and reducing costs and time-to-market for critical therapies. The sector’s relevance continues to grow due to rising biologics demand, government support for domestic manufacturing, and the shift toward precision medicine and personalized therapies.

Learn how the Next-Generation Biomanufacturing Market is evolving—insights, trends, and opportunities await. Download report: https://www.databridgemarketresearch.com/reports/global-next-generation-biomanufacturing-market

The Evolution

The evolution of biomanufacturing has progressed through distinct technological eras. Traditional biomanufacturing relied heavily on large-scale stainless-steel bioreactors, batch processing, and manual operations. These systems, while effective, were costly, inflexible, and time-intensive.

The late 20th century marked a shift toward recombinant DNA technology and monoclonal antibody (mAb) production, which significantly expanded the scope of biologics manufacturing. The introduction of single-use bioreactors in the early 2000s transformed production flexibility, enabling smaller batch sizes and reducing contamination risk.

Next-generation biomanufacturing emerged from the need to optimize these processes through automation, data analytics, and continuous manufacturing systems. Continuous bioprocessing enables real-time control of critical parameters, improving consistency and yield while minimizing waste. Digital technologies, such as machine learning and process analytical technology (PAT), now allow predictive process control, real-time quality monitoring, and rapid scalability.

The COVID-19 pandemic accelerated innovation and investment in this space, as biopharma companies required agile manufacturing to meet global vaccine and therapeutic demands. The market now stands as a core enabler of the future of biologics production, supporting speed, precision, and sustainability.

Market Trends

The next-generation biomanufacturing market is shaped by several key trends influencing global healthcare manufacturing and innovation.

1. Rise of Continuous and Hybrid Bioprocessing

Continuous bioprocessing is becoming a dominant approach due to its ability to maintain consistent product quality and reduce operational costs. Hybrid systems combining batch and continuous processes are widely adopted to balance flexibility and performance.

2. Growth of Single-Use Technologies

Disposable bioreactors, filters, and bags are replacing traditional stainless-steel systems. Single-use components reduce cleaning and validation requirements, minimize downtime, and enable multi-product manufacturing facilities.

3. Integration of Digitalization and Automation

The adoption of artificial intelligence (AI), digital twins, and advanced automation supports predictive maintenance, error reduction, and optimization of bioproduction. Smart biomanufacturing platforms are becoming standard across leading facilities.

4. Decentralized and Modular Manufacturing Facilities

Companies are investing in modular biomanufacturing units that can be rapidly deployed to different regions, enabling local production and enhancing supply chain resilience.

5. Rising Demand for Personalized Medicine

The increasing use of cell and gene therapies requires flexible, small-scale production systems. Next-generation biomanufacturing technologies enable rapid customization and scalability for personalized treatments.

6. Sustainability and Green Bioprocessing

Sustainability is a key focus area. The industry is investing in reducing energy consumption, water use, and waste generation, with circular economy principles guiding manufacturing practices.

7. Expansion of Contract Manufacturing Organizations (CMOs)

Biopharmaceutical companies increasingly outsource manufacturing to specialized CMOs that invest in next-generation technologies to offer high-quality, cost-efficient production.

Challenges

While the next-generation biomanufacturing market offers significant growth opportunities, it also faces several challenges.

1. High Capital Investment

The deployment of advanced manufacturing systems, automation technologies, and digital platforms requires substantial upfront investment, limiting adoption among small and mid-sized enterprises.

2. Technical Complexity

Implementing continuous and hybrid bioprocessing requires advanced process control and skilled personnel. The transition from batch to continuous processes remains challenging due to regulatory and technical constraints.

3. Regulatory Uncertainty

Regulatory frameworks are still adapting to emerging technologies. Agencies such as the FDA and EMA require rigorous validation and data integrity standards, which can delay technology deployment.

4. Supply Chain Vulnerabilities

Dependence on specialized equipment suppliers and materials exposes manufacturers to supply chain disruptions, particularly during global crises.

5. Workforce Training Gaps

The biomanufacturing workforce must adapt to digitalization and automation. A shortage of skilled professionals in bioinformatics, data analytics, and process automation is a limiting factor for many organizations.

6. Data Security and Integration

The integration of cloud-based process management systems introduces data privacy concerns and challenges in harmonizing legacy systems with modern digital platforms.

Market Scope

The global next-generation biomanufacturing market is categorized by type, application, technology, end-user, and region.

By Type:

-

Upstream Biomanufacturing

-

Downstream Biomanufacturing

-

Hybrid Systems

By Application:

-

Monoclonal Antibody Production

-

Vaccines

-

Recombinant Proteins

-

Cell and Gene Therapies

-

Other Biologics

By Technology:

-

Continuous Bioprocessing

-

Single-Use Bioprocessing Systems

-

AI and Automation-Driven Platforms

-

Modular and Flexible Manufacturing Units

By End User:

-

Biopharmaceutical Companies

-

Contract Manufacturing Organizations (CMOs)

-

Research and Academic Institutes

Regional Analysis:

-

North America: The largest market, driven by strong biopharma infrastructure, government funding, and early technology adoption in the United States.

-

Europe: Rapid integration of continuous manufacturing and sustainable production initiatives, supported by regulatory modernization.

-

Asia-Pacific: Fastest-growing region with significant investments in domestic biologics production, particularly in China, India, and South Korea.

-

Latin America: Emerging manufacturing hub supported by government incentives and growing healthcare investments.

-

Middle East & Africa: Developing interest in biopharmaceutical self-sufficiency and technology partnerships.

Market Size and Factors Driving Growth

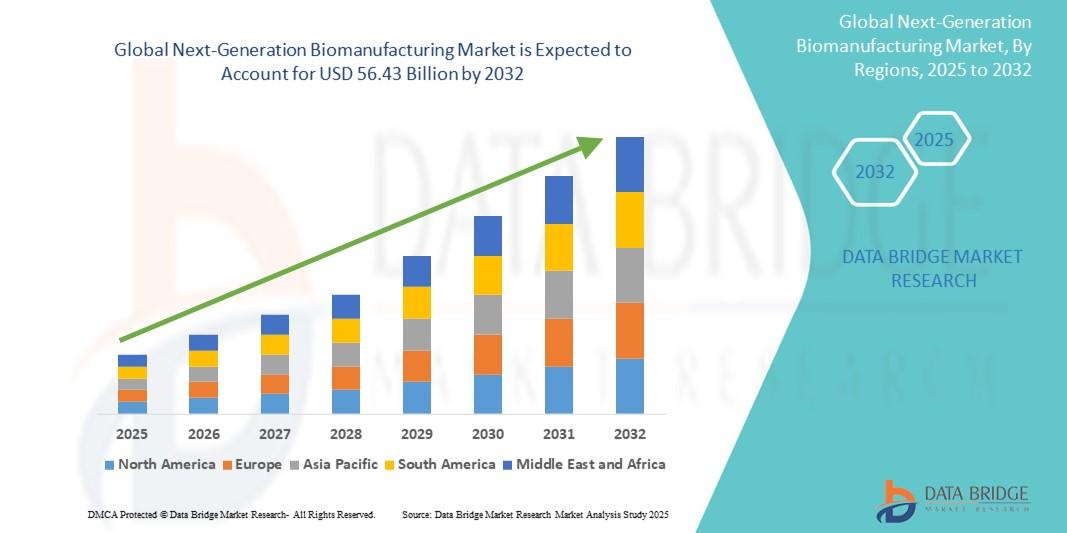

The global next-generation biomanufacturing market size was valued at USD 26.61 billion in 2024 and is expected to reach USD 56.43 billion by 2032, at a CAGR of 9.85% during the forecast period

Key Growth Factors:

1. Rising Demand for Biologics and Biosimilars

The global biopharmaceutical market continues to expand due to growing demand for monoclonal antibodies, vaccines, and biosimilars. Next-generation biomanufacturing enables cost-effective large-scale production to meet this demand.

2. Technological Advancements

Automation, robotics, and data analytics are transforming bioprocessing efficiency and scalability. Advanced sensors and real-time monitoring improve quality assurance and reduce production errors.

3. Growing Investments and Partnerships

Public and private sector funding is accelerating technology adoption. Strategic collaborations between biotechnology firms, CMOs, and equipment manufacturers are expanding manufacturing capabilities.

4. Increasing Focus on Personalized Therapies

The growing adoption of gene and cell therapies requires adaptable, small-batch manufacturing platforms, which next-generation systems are well-suited to support.

5. Government Support and Policy Initiatives

Countries are investing in domestic biomanufacturing capacity to ensure supply chain security and strengthen bioeconomy resilience.

6. Rising Adoption of Continuous Manufacturing

Continuous production reduces downtime, enhances productivity, and ensures consistent product quality, attracting widespread industry interest.

7. Sustainability Goals

Reduced water usage, waste generation, and carbon emissions in next-generation facilities align with global sustainability objectives and corporate ESG commitments.

Conclusion

The next-generation biomanufacturing market is poised to redefine the global biopharmaceutical landscape. Its integration of digital technologies, automation, and flexible production platforms supports rapid, sustainable, and cost-efficient manufacturing. The transition toward continuous and single-use systems marks a fundamental shift from traditional batch processes, enabling scalability and resilience in supply chains.

As the industry approaches 2035, growth will be driven by rising biologics demand, innovation in automation, and supportive regulatory modernization. Companies that invest in digital transformation, workforce training, and sustainable production will be well-positioned to lead the next phase of biomanufacturing evolution.

The market outlook remains highly promising, offering opportunities for technology developers, CMOs, and biopharma companies aiming to enhance productivity, reduce costs, and accelerate time-to-market for life-saving therapies.

Frequently Asked Questions (FAQ)

1. What is next-generation biomanufacturing?

Next-generation biomanufacturing refers to the use of advanced technologies such as continuous processing, single-use systems, and automation to improve the efficiency and sustainability of biologics production.

2. What is the current market size?

The global next-generation biomanufacturing market is valued at approximately USD 12.8 billion in 2024.

3. What is the projected market growth?

The market is expected to grow at a CAGR of 12.2% to reach USD 44.6 billion by 2035.

4. What factors are driving market growth?

Key drivers include increased biologics demand, technological innovation, government support, and the need for flexible and sustainable manufacturing solutions.

5. Which regions lead the market?

North America and Europe currently lead the market, while Asia-Pacific is emerging as the fastest-growing region.

6. What are the main challenges?

Major challenges include high implementation costs, regulatory uncertainty, supply chain risks, and a shortage of skilled labor.

7. What technologies define next-generation biomanufacturing?

Core technologies include continuous bioprocessing, single-use systems, automation, AI-driven process control, and modular manufacturing.

8. What are future opportunities for investors and manufacturers?

Investments in smart manufacturing, cell and gene therapy production, and sustainable technologies present major growth opportunities through 2035.

Browse More Reports:

Global Fracking Water Treatment Market

Global Giardiasis Treatment Market

Global High Purity Limestone Market

Global Luciferase Assay Kits Market

Global RF Over Fiber Market

Global Solar Photovoltaic (PV) Mounting Systems Market

Global Handheld Intraoral Dental 3D Scanners Market

Global Metalworking Fluid Additives Market

Global Pet Food Flavors Market

Global Polypropylene Compounds Market

Global Time Temperature Indicator Labels Market

Global Digital X-Ray Market

Global Insulin Delivery Devices Market

Global Acrylonitrile Butadiene Rubber (BR) Market

Global Aerogel Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"

- Art

- Education et Formation

- Crafts

- Sciences et Technologies

- Economie

- Politique

- Actualité

- Littérature

- Divertissement

- Histoire

- Health

- Actualité

- Shopping & Commerce

- Music

- Agriculture & élevage

- Voyage et Evènementiel

- Beauté & esthétique

- Religion

- Festival

- Sports

- Fête

- Musique

- Autres