Laser Cutting Machines Market Trends and Emerging Opportunities

Introduction

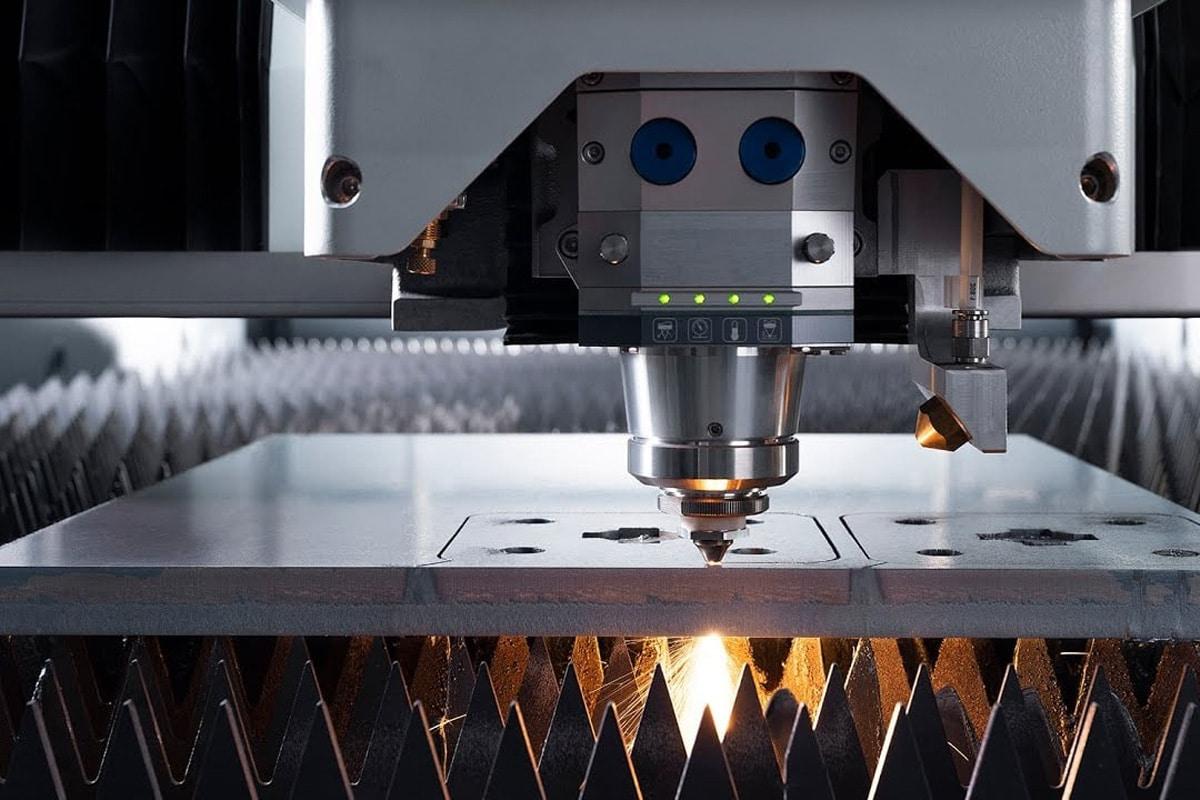

The laser cutting machines market is a key segment of the advanced manufacturing and fabrication industry, enabling high-precision cutting, engraving, and shaping of materials across diverse applications. Laser cutting machines use focused laser beams to cut materials such as metals, plastics, composites, wood, textiles, and glass with exceptional accuracy and minimal material waste. These machines are widely adopted in industries including automotive, aerospace, electronics, metal fabrication, construction, and consumer goods manufacturing.

As manufacturers seek higher productivity, tighter tolerances, and greater design flexibility, laser cutting has become a preferred alternative to conventional mechanical cutting methods. Advancements in laser sources, control software, and automation are enhancing cutting speed, quality, and energy efficiency. With growing emphasis on smart manufacturing and precision engineering, the laser cutting machines market is experiencing steady global growth.

Market Drivers

One of the primary drivers of the laser cutting machines market is the increasing demand for precision manufacturing. Industries such as automotive, aerospace, and electronics require complex geometries, fine tolerances, and consistent quality, which laser cutting machines can deliver reliably. The ability to produce intricate designs without tool wear or frequent setup changes makes laser cutting highly attractive for modern production environments.

Growth in metal fabrication and industrial manufacturing is another major driver. Laser cutting machines are extensively used for sheet metal processing, structural components, and customized parts. Expansion of infrastructure projects, industrial equipment manufacturing, and construction activities is increasing demand for efficient and flexible cutting solutions, supporting market growth.

Technological advancements are also accelerating adoption. Developments in fiber laser technology have significantly improved cutting speed, energy efficiency, and maintenance requirements compared to traditional CO₂ lasers. Integration of computer numerical control, automation, and real-time monitoring systems is enhancing productivity and reducing labor dependency, further driving market expansion.

Market Challenges

Despite strong demand, the laser cutting machines market faces several challenges. High initial investment costs can be a barrier, particularly for small and medium-sized enterprises. Advanced laser cutting systems equipped with high-power lasers, automation, and safety features require substantial capital expenditure, which may limit adoption in cost-sensitive markets.

Operational complexity and skill requirements present additional challenges. Although laser cutting machines are highly automated, proper setup, programming, and maintenance require skilled operators and technicians. Shortages of trained personnel can affect machine utilization and increase operating costs for manufacturers.

Maintenance and component costs also pose challenges. Laser sources, optics, and cooling systems require regular maintenance to ensure consistent performance. Replacement of high-precision components can be expensive, impacting total cost of ownership, especially for high-power industrial systems.

Market Opportunities

The rise of smart manufacturing and Industry 4.0 presents significant opportunities for the laser cutting machines market. Integration of sensors, data analytics, and connectivity enables predictive maintenance, process optimization, and real-time quality control. Smart laser cutting systems improve uptime, reduce waste, and enhance overall production efficiency.

Growing demand for customized and low-volume production offers another major opportunity. Laser cutting machines support rapid prototyping and flexible manufacturing without the need for dedicated tooling. This capability is particularly valuable for small batch production, product customization, and design-intensive industries.

Emerging markets represent strong growth potential. Rapid industrialization, expansion of manufacturing capacity, and government initiatives promoting domestic production in regions such as Asia-Pacific, Latin America, and parts of the Middle East are driving demand for advanced fabrication equipment. Investment in metalworking and electronics manufacturing is expected to further support market growth in these regions.

Regional Insights

Asia-Pacific holds a leading position in the laser cutting machines market due to its large manufacturing base and strong presence of metal fabrication and electronics industries. Countries such as China, Japan, South Korea, and India are major consumers of laser cutting technology, supported by industrial expansion and export-oriented manufacturing.

Europe represents another significant market, driven by advanced engineering capabilities and high demand for precision manufacturing. The region’s automotive, aerospace, and industrial machinery sectors rely heavily on laser cutting for high-quality and complex components. Adoption of energy-efficient and automated laser systems is further supporting market growth.

North America also contributes substantially to the market, supported by technological innovation and modernization of manufacturing facilities. Demand from aerospace, defense, automotive, and custom fabrication sectors is driving adoption of advanced laser cutting machines across the region.

Future Outlook

The future of the laser cutting machines market is closely linked to ongoing advancements in laser technology, automation, and digital manufacturing. Fiber lasers are expected to gain a larger share due to their efficiency, reliability, and lower operating costs. Increased use of artificial intelligence and machine learning in process control will further enhance cutting accuracy and productivity.

As manufacturers focus on flexibility, sustainability, and cost optimization, demand for advanced laser cutting solutions is expected to remain strong. Integration with smart factory systems and adoption of digital workflows will continue to shape the evolution of laser cutting machines, supporting long-term market growth.

Conclusion

The laser cutting machines market is a vital enabler of precision manufacturing and advanced fabrication across multiple industries. Driven by demand for high accuracy, flexibility, and efficiency, the market continues to grow steadily worldwide. While challenges related to cost, skill requirements, and maintenance persist, technological innovation and expansion of smart manufacturing are creating strong growth opportunities. As industrial production becomes more complex and quality-driven, laser cutting machines will remain essential tools in modern manufacturing.

- Art

- Education et Formation

- Crafts

- Sciences et Technologies

- Economie

- Politique

- Actualité

- Littérature

- Divertissement

- Histoire

- Health

- Actualité

- Shopping & Commerce

- Music

- Agriculture & élevage

- Voyage et Evènementiel

- Beauté & esthétique

- Religion

- Festival

- Sports

- Fête

- Musique

- Autres