Why Short Glass Fiber Reinforced PBT market Is Expanding: Market Trends, Forecasts & Investment Potential

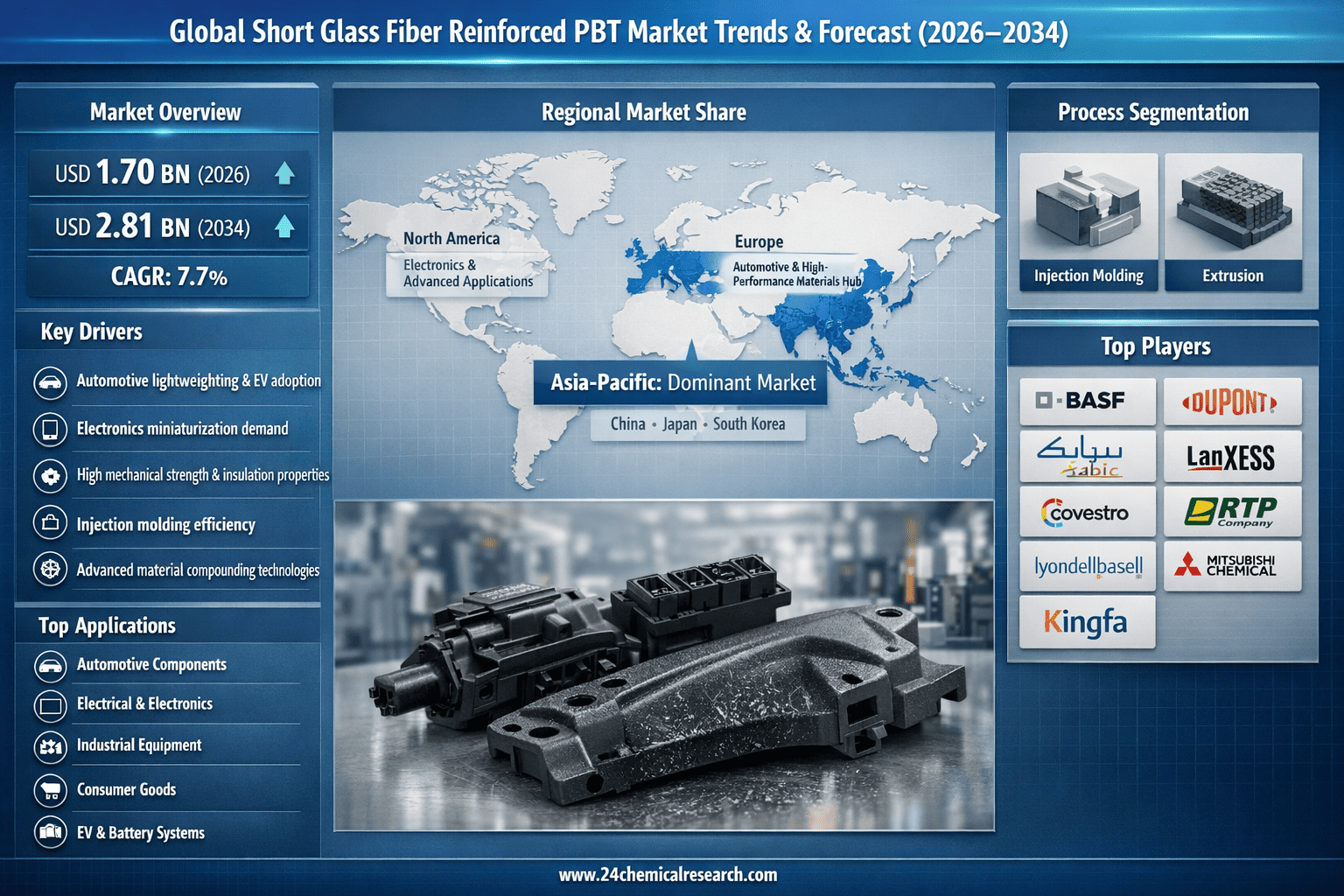

According to 24Chemical Research, Global Short Glass Fiber Reinforced PBT market was valued at USD 1.70 billion in 2026 and is projected to reach USD 2.81 billion by 2034, exhibiting a remarkable CAGR of 7.7% during the forecast period.

Short Glass Fiber Reinforced PBT (SFR-PBT) represents a high-performance thermoplastic composite engineered by integrating polybutylene terephthalate resin with precisely cut glass fibers, typically ranging from 0.2-4.5 mm in length. This material has transitioned from specialized applications to become a fundamental component across multiple industries due to its exceptional mechanical strength, dimensional stability, and superior electrical insulation properties. Unlike many alternative materials, SFR-PBT maintains excellent processability on conventional injection molding equipment while offering enhanced performance characteristics that make it indispensable for precision components in demanding environments.

Get Full Report Here: https://www.24chemicalresearch.com/reports/299921/short-glass-fiber-reinforced-pbt-market

Market Dynamics:

The market's development is governed by a complex interaction of robust growth catalysts, significant adoption barriers that industry participants are actively addressing, and substantial emerging opportunities across various sectors.

Powerful Market Drivers Propelling Expansion

-

Automotive Industry Transformation and Lightweighting Initiatives: The global automotive sector's relentless pursuit of weight reduction represents the primary growth vector for SFR-PBT. This material enables manufacturers to replace metal components with lighter alternatives that maintain structural integrity while improving fuel efficiency. The transition toward electric vehicles has further accelerated adoption, as SFR-PBT's excellent electrical properties and thermal stability make it ideal for battery housings, charging components, and sensor systems. Major automotive manufacturers increasingly specify SFR-PBT for under-the-hood applications where temperatures can exceed 120°C, demonstrating the material's critical role in modern vehicle design.

-

Electronics Miniaturization and Performance Demands: The electronics industry continues to drive substantial demand through its need for materials that support device miniaturization while maintaining performance standards. SFR-PBT's combination of high rigidity, excellent dielectric strength, and resistance to warping makes it particularly valuable for connectors, sockets, and miniature components in consumer electronics and industrial equipment. The material's ability to maintain dimensional stability under thermal stress ensures reliable performance in increasingly compact electronic devices where space constraints and heat management present significant engineering challenges.

-

Material Advancements and Processing Efficiency: Continuous improvements in compounding technology and fiber-matrix adhesion have enhanced the mechanical properties and processability of SFR-PBT grades. These advancements allow manufacturers to produce more complex geometries with thinner walls while maintaining structural integrity. The material's excellent flow characteristics enable faster cycle times and reduced energy consumption during manufacturing, providing economic benefits that extend beyond the material's performance advantages to encompass overall production efficiency.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/299921/short-glass-fiber-reinforced-pbt-market

Significant Market Restraints Challenging Adoption

Despite the compelling advantages, several factors temper the market's growth trajectory and present challenges that require strategic management.

-

Raw Material Price Volatility and Supply Chain Dependencies: The production cost structure of SFR-PBT is heavily influenced by petrochemical feedstock prices, particularly for PBT resin which constitutes 65-75% of the total material cost. Fluctuations in crude oil markets directly impact production economics, creating pricing uncertainty throughout the value chain. Additionally, the specialized glass fibers require energy-intensive manufacturing processes, making their cost susceptible to energy market dynamics. This dual dependency on volatile raw material markets presents persistent challenges for cost management and pricing stability.

-

Technical Processing Complexities and Material Limitations: The incorporation of glass fibers introduces specific processing challenges that can limit adoption among manufacturers without specialized expertise. Anisotropic shrinkage during molding can lead to warpage in complex parts, requiring sophisticated mold design and process control. Additionally, while SFR-PBT offers excellent chemical resistance to many substances, it remains susceptible to hydrolysis when exposed to high-temperature water or steam, and can be degraded by strong acids and bases. These limitations necessitate careful material selection and design considerations for applications in harsh chemical environments.

Critical Market Challenges Requiring Innovation

The transition from material development to industrial implementation presents distinct challenges that the industry must overcome to realize SFR-PBT's full potential.

Maintaining consistent fiber dispersion and orientation in high-volume production runs remains technically demanding, with variations potentially affecting mechanical properties in finished components. The abrasive nature of glass fibers accelerates wear on processing equipment, particularly injection molding screws and barrels, necessitating specialized hardened components and increasing maintenance costs. Furthermore, achieving optimal fiber-matrix adhesion requires precise control of compounding parameters, with deviations potentially compromising the material's performance characteristics.

Additionally, the market faces evolving regulatory requirements regarding material composition and environmental impact. Compliance with various international standards for flame retardancy, food contact, and automotive applications requires continuous testing and certification efforts. The complex global regulatory landscape necessitates significant investment in compliance management and documentation, particularly for manufacturers serving multiple geographic markets with differing requirements.

Vast Market Opportunities on the Horizon

-

Sustainable Material Development and Circular Economy Integration: The growing emphasis on sustainability presents significant opportunities for developing recycled-content and bio-based SFR-PBT formulations. Success in creating high-performance sustainable grades would align with corporate environmental mandates and regulatory trends while addressing end-user demands for greener material options. Advanced recycling technologies that can effectively separate and reuse glass fiber reinforced polymers could create new value streams and reduce the environmental impact of SFR-PBT components at end-of-life.

-

Advanced Application Development in Emerging Technologies: The rapid expansion of 5G infrastructure, IoT devices, and renewable energy systems creates new application opportunities that leverage SFR-PBT's unique property combination. The material's excellent dielectric properties make it suitable for high-frequency applications in communications equipment, while its durability and weatherability support use in outdoor renewable energy components. These emerging applications represent growth vectors beyond the traditional automotive and electronics sectors, diversifying the market's application base.

-

Hybrid Material Systems and Multi-functional Composites: Development of advanced compound formulations that combine glass fibers with other reinforcement materials or functional additives presents opportunities for creating materials with tailored property profiles. These hybrid systems can address specific application requirements that cannot be met by standard SFR-PBT grades, enabling penetration into new market segments and applications. The integration of conductive fillers, antimicrobial additives, or other functional components can transform SFR-PBT from a structural material into a multi-functional solution.

In-Depth Segment Analysis: Where is the Growth Concentrated?

By Type:

The market is segmented primarily by processing method, with Injection Molding and Extrusion representing the main categories. Injection Molding dominates the market due to its suitability for high-volume production of complex, precision components. This method leverages the material's excellent flow characteristics and rapid crystallization behavior to produce parts with consistent quality and dimensional accuracy. The extrusion process caters to applications requiring continuous profiles or sheets, though it represents a smaller segment of the overall market.

By Application:

Application segments include Automotive, Electrical & Electronics, Industrial Equipment, Consumer Goods, and Others. The Electrical & Electronics segment currently represents the largest application area, driven by the material's excellent electrical insulation properties, heat resistance, and ability to meet stringent flame retardancy standards. The automotive segment follows closely, with strong growth driven by lightweighting initiatives and the transition to electric vehicles. Both sectors leverage SFR-PBT's combination of mechanical performance, dimensional stability, and processing efficiency.

By End-User Industry:

The end-user landscape encompasses Automotive Manufacturing, Electronics Production, Industrial Equipment, Consumer Products, and Other Industries. The Electronics industry accounts for the largest share, utilizing SFR-PBT for components that require precision, reliability, and compliance with industry standards. The automotive sector represents another major end-user, with applications ranging from structural components to electrical systems. Both industries continue to drive innovation in material development to meet evolving performance requirements.

Download FREE Sample Report: BASF (Germany)

-

DuPont (USA)

-

SABIC (Saudi Arabia)

-

Lanxess (Germany)

-

Covestro (Germany)

-

极速11选5有什么规律

-

RTP Company (USA)

-

LyondellBasell (Netherlands)

-

Evonik (Germany)

-

Mitsubishi Chemical (Japan)

-

Kingfa (China)

-

Shanghai PRET Composites (China)

-

-

Competition centers on developing advanced formulations with improved properties, enhancing production efficiency, and expanding application capabilities. Companies are increasingly focusing on developing sustainable solutions and forming strategic partnerships with end-users to co-create application-specific materials that address evolving market requirements.

Regional Analysis: A Global Footprint with Distinct Leaders-

Asia-Pacific: This region dominates the global market, accounting for the largest share of both production and consumption. The concentration of electronics manufacturing, particularly in China, South Korea, and Japan, drives substantial demand. The region's rapidly expanding automotive industry, especially the growth of electric vehicle production in China, further reinforces its leadership position. Well-established supply chains, competitive manufacturing capabilities, and strong government support for industrial development contribute to Asia-Pacific's central role in the SFR-PBT market.

-

Europe & North America: These mature markets represent significant centers for innovation and high-value applications. Europe's strong automotive industry, particularly in Germany and France, drives demand for advanced materials that support lightweighting and electrification initiatives. North America maintains a strong position in specialized applications, particularly in the electronics and aerospace sectors. Both regions feature stringent regulatory environments that influence material development and create demand for high-performance, compliant materials.

-

极速11选5有什么规律

Rest of World: Emerging markets in South America, Middle East, and Africa present growing opportunities as industrialization progresses and local manufacturing capabilities develop. These regions are increasingly incorporating SFR-PBT into their industrial ecosystems, particularly as global supply chains diversify and local content requirements influence material sourcing decisions.

-

-

Get Full Report Here: https://www.24chemicalresearch.com/reports/299921/short-glass-fiber-reinforced-pbt-market

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/299921/short-glass-fiber-reinforced极速11选5有什么规律

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.-

Plant-level capacity tracking

-

Real-time极速11选5有什么规律 monitoring

-

Techno-economic feasibility studies

-

-

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

- Art

- Education et Formation

- Crafts

- Sciences et Technologies

- Economie

- Politique

- Actualité

- Littérature

- Divertissement

- Histoire

- Health

- Actualité

- Shopping & Commerce

- Music

- Agriculture & élevage

- Voyage et Evènementiel

- Beauté & esthétique

- Religion

- Festival

- Sports

- Fête

- Musique

- Autres